КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

Management of work of final settling tank

Lectures 8-9.

Biofiltration is a pollution control technique using living material to capture and biologically degrade process pollutants. Common uses include processing waste water, capturing harmful chemicals or silt from surface runoff, and microbiotic oxidation of contaminants in air.

When applied to air filtration and purification, biofilters use microorganisms to remove air pollution. The air flows through a packed bed and the pollutant transfers into a thin biofilm on the surface of the packing material. Microorganisms, including bacteria and fungi are immobilized in the biofilm and degrade the pollutant. Trickling filters and bioscrubbers rely on a biofilm and the bacterial action in their recirculating waters.

The technology finds greatest application in treating malodorous compounds and water-soluble volatile organic compounds (VOCs). Industries employing the technology include food and animal products, off-gas from wastewater treatment facilities, pharmaceuticals, wood products manufacturing, paint and coatings application and manufacturing and resin manufacturing and application, etc. Compounds treated are typically mixed VOCs and various sulfur compounds, including hydrogen sulfide. Very large airflows may be treated and although a large area (footprint) has typically been required -- a large biofilter (>200,000 acfm) may occupy as much or more land than a football field -- this has been one of the principal drawbacks of the technology. Engineered biofilters, designed and built since the early 1990s, have provided significant footprint reductions over the conventional flat-bed, organic media type.

Air cycle system at biosolids composting plant. Large duct in foreground is exhaust air into biofilter shown in next photo

Biosolids composting plant biofilter mound - note sprinkler visible front right to maintain proper moisture level for optimum functioning.

One of the main challenges to optimum biofilter operation is maintaining proper moisture throughout the system. The air is normally humidified before it enters the bed with a watering (spray) system, humidification chamber, bioscrubber, or biotrickling filter. Properly maintained, a natural, organic packing media like peat, vegetable mulch, bark or wood chips may last for several years but engineered, combined natural organic and synthetic component packing materials will generally last much longer, up to 10 years. A number of companies offer these types or proprietary packing materials and multi-year guarantees, not usually provided with a conventional compost or wood chip bed biofilter.

Although widely employed, the scientific community is still unsure of the physical phenomena underpinning biofilter operation, and information about the microorganisms involved continues to be developed. A biofilter/bio-oxidation system is a fairly simple device to construct and operate and offers a cost-effective solution provided the pollutant is biodegradable within a moderate time frame (increasing residence time = increased size and capital costs), at reasonable concentrations (and lb/hr loading rates) and that the airstream is at an organism-viable temperature. For large volumes of air, a biofilter may be the only cost-effective solution. There is no secondary pollution (unlike the case of incineration where additional CO2 and NOx are produced from burning fuels) and degradation products form additional biomass, carbon dioxide and water. Media irrigation water, although many systems recycle part of it to reduce operating costs, has a moderately high biochemical oxygen demand (BOD) and may require treatment before disposal. However, this "blowdown water", necessary for proper maintenance of any bio-oxidation system, is generally accepted by municipal POTWs without any pretreatment.

Biofilters are being utilized in Columbia Falls, Montana at Plum Creek Timber Company's fiberboard plant. The biofilters decrease the pollution emitted by the manufacturing process and the exhaust emitted is 98% clean. The newest, and largest, biofilter addition to Plum Creek cost $9.5 million, yet even though this new technology is expensive, in the long run it will cost less overtime than the alternative exhaust-cleaning incinerators fueled by natural gas (which are not as environmentally friendly). The biofilters use trillions of microscopic bacteria that cleanse the air being released from the plant.

A biofilm is an aggregate of microorganisms in which cells adhere to each other on a surface. These adherent cells are frequently embedded within a self-produced matrix of extracellular polymeric substance (EPS). Biofilm EPS, which is also referred to as slime (although not everything described as slime[disambiguation needed] is a biofilm), is a polymeric conglomeration generally composed of extracellular DNA, proteins, and polysaccharides. Biofilms may form on living or non-living surfaces and can be prevalent in natural, industrial and hospital settings. The microbial cells growing in a biofilm are physiologically distinct from planktonic cells of the same organism, which, by contrast, are single-cells that may float or swim in a liquid medium.

Microbes form a biofilm in response to many factors, which may include cellular recognition of specific or non-specific attachment sites on a surface, nutritional cues, or in some cases, by exposure of planktonic cells to sub-inhibitory concentrations of antibiotics.[3][4] When a cell switches to the biofilm mode of growth, it undergoes a phenotypic shift in behavior in which large suites of genes are differentially regulated (Stages of biofilm development).

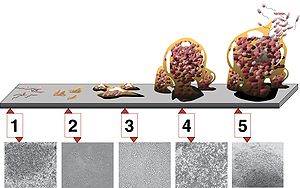

Picture 4. Five stages of biofilm development: (1) Initial attachment, (2) Irreversible attachment, (3) Maturation I, (4) Maturation II, and (5) Dispersion. Each stage of development in the diagram is paired with a photomicrograph of a developing P. aeruginosa biofilm. All photomicrographs are shown to same scale.

Biofilms are ubiquitous. Nearly every species of microorganism, not only bacteria and archaea, have mechanisms by which they can adhere to surfaces and to each other. Biofilms will form on virtually every non-shedding surface in a non-sterile aqueous (or very humid) environment.

Biofilms can be found on rocks and pebbles at the bottom of most streams or rivers and often form on the surface of stagnant pools of water. In fact, biofilms are important components of food chains in rivers and streams and are grazed by the aquatic invertebrates upon which many fish feed.

Biofilms can grow in the most extreme environments: from, for example, the extremely hot, briny waters of hot springs ranging from very acidic to very alkaline, to frozen glaciers.

In the human environment, biofilms can grow in showers very easily since they provide a moist and warm environment for the biofilm to thrive. Biofilms can form inside water and sewage pipes and cause clogging and corrosion. Biofilms on floors and counters can make sanitation difficult in food preparation areas.

Biofilms in cooling- or heating-water systems are known to reduce heat transfer.

Biofilms in marine engineering systems, such as pipelines of the offshore oil and gas industry, can lead to substantial corrosion problems. Corrosion is mainly due to abiotic factors; however, at least 20% of corrosion is caused by microorganisms that are attached to the metal subsurface (i.e., microbially-influenced corrosion).

Bacterial adhesion to boat hulls serves as the foundation for biofouling of seagoing vessels. Once a film of bacteria forms, it is easier for other marine organisms such as barnacles to attach. Such fouling can reduce maximum vessel speed by up to 20%, prolonging voyages and consuming fuel. Time in dry dock for refitting and repainting reduces the productivity of shipping assets, and the useful life of ships is also reduced due to corrosion and mechanical removal (scraping) of marine organisms from ships' hulls.

Biofilms can also be harnessed for constructive purposes. For example, many sewage treatment plants include a treatment stage in which waste water passes over biofilms grown on filters, which extract and digest organic compounds. In such biofilms, bacteria are mainly responsible for removal of organic matter (BOD), while protozoa and rotifers are mainly responsible for removal of suspended solids (SS), including pathogens and other microorganisms. Slow sand filters rely on biofilm development in the same way to filter surface water from lake, spring or river sources for drinking purposes. What we regard as clean water is a waste material to these microcellular organisms since they are unable to extract any further nutrition from the purified water.

Biofilms can help eliminate petroleum oil from contaminated oceans or marine systems. The oil is eliminated by the hydrocarbon-degrading activities of microbial communities, in particular by a remarkable recently-discovered group of specialists, the so-called hydrocarbonoclastic bacteria (HCB).

Stromatolites are layered accretionary structures formed in shallow water by the trapping, binding and cementation of sedimentary grains by microbial biofilms, especially of cyanobacteria. Stromatolites include some of the most ancient records of life on Earth, and are still forming today.

Biofilms are present on the teeth of most animals as dental plaque, where they may cause tooth decay and gum disease.

Biofilms are found on the surface of and inside plants. They can either contribute to crop disease or, as in the case of nitrogen-fixing Rhizobium on roots, exist symbiotically with the plant. Examples of crop diseases related to biofilms include Citrus Canker, Pierce's Disease of grapes, and Bacterial Spot of plants such as peppers and tomatoes.

Biofilms are used in microbial fuel cells (MFCs) to generate electricity from a variety of starting materials, including complex organic waste and renewable biomass.

Control questions:

- What Is Biofilm?

- Is Biofilm on Your Oral Appliances?

- Biofilm and Your Health?

- Chemical Control of Biofilm?

|

|

Дата добавления: 2014-10-15; Просмотров: 463; Нарушение авторских прав?; Мы поможем в написании вашей работы!