КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

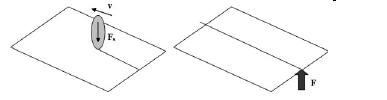

Glass cutting principle (scribing, flexuring)

|

|

|

|

CUTTING AND DRILLING OF GLASS

Another important aspect of contact behavior of glass is the cutting and drilling of glass sheets. Cutting is divided into three operations: scribing, flexuring and breaking.

Scribing of the glass under a sharp tip (in fact a glass-cutter wheel) allows the generation of median cracks similar to those described under a sharp indenter (one observes that for scribing a lateral movement is to be added. The applied vertical force Fs while scribing has to be controlled carefully to introduce median cracks while avoiding the generation of lateral ones that yield chips and degrade the glazing edge quality. Subsequently, the introduced median cracks are driven through the glass thickness applying tensile stresses on the indented side by bending the glazing. Scribing of good quality is achieved using sharp rollers to mark the glass and cutting oil to protect the mark from the atmosphere and so from ageing.

Cutting oil is applied on the glass surface with a pad in front of the cutting head. The plate is then bent setting the crack tip under tensile stresses to force its operations are carried out automatically on float lines.

The success of this procedure depends on the control of crack generation and flexure stress, and also on the amplitude of residual stresses that may appear during the cooling of the glass. Because of the development of thin glass and fibres, laser cutting has been developed. Thermal shock induced by the laser allows for crack formation and further development. For very thin glass (also fibres) laser-induced melting permits the direct separation (cutting) of the two pieces. One advantage of laser cutting is that in principle operations like grinding can be avoided.

|

|

|

|

|

Дата добавления: 2015-01-03; Просмотров: 369; Нарушение авторских прав?; Мы поможем в написании вашей работы!