КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

Containers

|

|

|

|

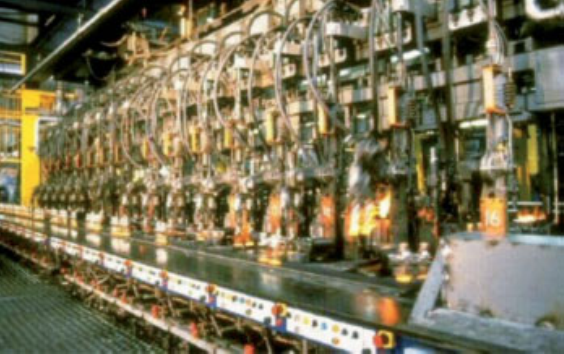

Containers include packaging (bottles, cans, jars, flasks) and glassware (plates, dishes, bowls, glass, moulds) that are formed at large scale by pressing and/or blowing a glass gob into a forming mould. Packaging and glass ware utilize glass optical transparency and/or UV protection combined with chemical inertness (for contained food or liquid). As a result of its durability, glass is also useful as a container for corrosive fluids, or liners for chemical reactors. For pharmaceutical packaging, borosilicate glasses a preferred to standard silica- soda lime since they are more chemically resistant. In fact, standard glass is not completely inert since mobile alkaline ions may be leached into the contained product.

Therefore, low alkaline concentration glass containers have been developed. In the field of elevated temperature applications, low thermal expansion glasses are used. Pyrex glass is the most well-known. Some manufacturers also tried to develop tempered containers from standard glass for the same purpose. These resist unless thermal shock stresses exceed the built-in residual stresses and then brittle fracture happens generating several pieces of glass. Glass containers were much utilized going back some decades since they could be reused. Glass presents several advantages as a packaging material:

* chemical inertness;

* ability to be recycled;

* non-polluting nature on ultimate disposal;

* ability to be manufactured from abundant raw materials;

* UV filtration (amber and green glass), optical and transparency qualities;

* low gas permeability;

* high intrinsic strength.

Despite these advantages, glass-packaged products face significant competitive pressures from products made of alternative materials. Nowadays, plastic, paper and related material, and metallic (aluminium and steel) containers share a large part of the container market, although some of them cost sometimes more than they contain. This has forced the glass industry to produce lighter containers for short-term conservation purposes while offering new attractive designs and promoting glass recycling. Metallic can manufacturers are developing environmentally friendly technology which allows for recycling as well.

For long-term conservation (e.g. liquors, wines, champagne) glass tends to be preferred to  other materials because of its low permeability to gas and because of its chemical stability. By the way, marketing is a complex issue: glass still provides superior taste, health, visual appeal and value. One expects champagne to be contained in a heavy glass bottle! In term so R&D there are opportunities for science and chemistry to produce new colorations and new design technology being environment friendly. When considered for short-term conservation containers, these new functions are to be produced at similar industrial costs otherwise other materials compete dramatically.

other materials because of its low permeability to gas and because of its chemical stability. By the way, marketing is a complex issue: glass still provides superior taste, health, visual appeal and value. One expects champagne to be contained in a heavy glass bottle! In term so R&D there are opportunities for science and chemistry to produce new colorations and new design technology being environment friendly. When considered for short-term conservation containers, these new functions are to be produced at similar industrial costs otherwise other materials compete dramatically.

The situation is much different for cosmetics and fragrance packaging where design plays a very important place in the marketing of the product. Dedicated compositions of glass are being employed, for instance colored transition and opal glasses (so called milk glass). Also, lead crystal glass ware offers great flexibility as revealed by art glass development and industrial tools being adapted to the low-viscosity regime. Blowing, flame-working and hot-glass sculpting are however still employed and developed in this area.

|

|

|

|

|

Дата добавления: 2015-01-03; Просмотров: 425; Нарушение авторских прав?; Мы поможем в написании вашей работы!