КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

Water Pump. Be careful not to damage the sealing surface of the mechanical seal

|

|

|

|

COOLING SYSTEM

Be careful not to damage the sealing surface of the mechanical seal.

CAUTION

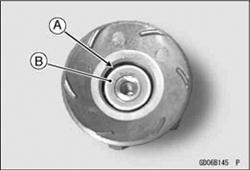

Take the oil seal [A] out of the housing [B] with a hook [C].

• Press the mechanical seal [A] out of the housing with a bearing driver [B].

Special Tool - Bearing Driver Set: 57001-1129

Water Pump Housing Assembly

• Apply a high temperature grease [A] to the oil seal [B].

• Press the oil seal into the housing with a bearing driver until it stops at the bottom surface of the housing [C].

• Press the mechanical seal into the housing with a bearing driver [D] until its flange [E] touches the surface [F] of the housing.

Special Tool - Bearing Driver Set: 57001-1129

|

|

Impeller Assembly

• Clean the sliding surface of the mechanical seal with a high flash-point solvent, and apply a little coolant to the sliding surface to give the mechanical seal initial lubrication.

• Apply coolant to the surfaces of the rubber seal [A] and sealing seat [B], and install the rubber seal and sealing seat into the impeller by pressing them by hand until the seat stops at the bottom of the hole.

Pump Impeller Inspection

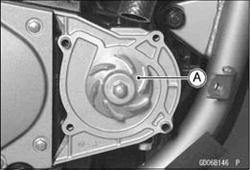

• Visually check the impeller [A].

• If the surface is corroded, or if the blades are damaged, replace the impeller.

|

|

|

|

|

Дата добавления: 2014-12-23; Просмотров: 409; Нарушение авторских прав?; Мы поможем в написании вашей работы!