КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

Caution. Operating Procedures caution Do not grind the seat too much

|

|

|

|

NOTE

Valves

ENGINE TOP END 5-29

Operating Procedures

| CAUTION |

| Do not grind the seat too much. Overgrinding will reduce valve clearance by sinking the valve into the head. If the valve sinks too far into the head, it will be impossible to adjust the clearance, and the cylinder head must be replaced. |

• Clean the seat area carefully.

• Coat the seat with machinist’s dye.

• Fit a 45° cutter to the holder and slide it into the valve guide.

• Press down lightly on the handle and turn it right or left. Grind the seating surface only until it is smooth.

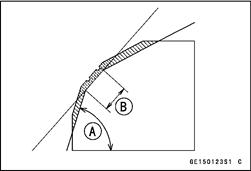

[A] Grind the seat at a 45° angle to enlarge the width of the seating surface.

[B] 32° cut

[C] 32°

[D] Specified seating surface width

[E] 60° cut

[F] 60°

•  Measure the outside diameter (O.D.) of the seating surface with a vernier caliper.

Measure the outside diameter (O.D.) of the seating surface with a vernier caliper.

• If the outside diameter of the seating surface is too small, repeat the 45° grind [A] until the diameter is within the specified range.

Original Seating Surface [B]

ORemove all pittings of flaws from 45° ground surface.

О After grinding with 45° cutter, apply thin coat of machinist’s dye to seating surface. This makes seating surface distinct and 32° and 60° grinding operation easier.

О When the valve guide is replaced, be sure to grind with 45° cutter for centering and good contact.

• If the outside diameter of the seating surface is too large, make the 32° grind described below.

• If the outside diameter [A] of the seating surface is within the specified range, measure the seat width as described below.

• Grind the seat at a 32° angle [B] until the seat O.D. is within the specified range.

OTo make the 32° grind, fit a 32° cutter to the holder, and

slide it into the valve guide. OTurn the holder one turn at a time while pressing down

very lightly. Check the seat after each turn.

|

The 32° cutter removes material very quickly. Check the seat outside diameter frequently to prevent overgrinding.

|

OAfter making the 32° grind, return to the seat O.D. measurement step above.

• To measure the seat width, use a vernier caliper to measure the width of the 45° angle portion of the seat at several places around the seat.

• If the seat width is too narrow, repeat the 45° grind until the seat is slightly too wide, and then return to the seat O.D. measurement step above.

• If the seat width is too wide, make the 60° [A] grind described below.

• If the seat width is within the specified range, lap the valve to the seat as described below.

• Grind the seat at a 60° angle until the seat width is within the specified range.

OTo make the 60° grind, fit a 60° cutter to the holder, and slide it into the valve guide.

OTurn the holder, while pressing down lightly.

OAfter making the 60° grind, return to the seat width measurement step above. Correct Width [B]

|

|

|

|

|

Дата добавления: 2014-12-23; Просмотров: 409; Нарушение авторских прав?; Мы поможем в написании вашей работы!