КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

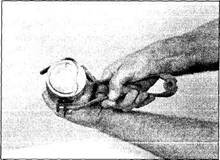

Use old feeler gauge blades to carefully expand the piston rings

|

|

|

|

A large socket can be used to drive the new core plugs into the bores

All bolt holes in the block should be cleaned and restored with a tap

Engine removal and overhaul procedures 2E•9

old feeler blades will be helpful in preventing the rings dropping into empty grooves (see illustration). Be careful not to scratch thepiston with the ends of the ring. The rings are brittle, and will snap if they are spread too far. They are also very sharp - protect your hands and fingers.

3 Scrape all traces of carbon from the top of the piston. A hand-held wire brush or a piece of fine emery cloth can be used once the majority of the deposits have been scraped away. Do not, under any circumstances, use a wire brush mounted in a drill motor to remove deposits from the pistons. The piston material is soft and may be eroded away by the wire brush.

4 Use a piston ring groove-cleaning tool to remove carbon deposits from the ring grooves. If a tool isn't available, a piece broken off the old ring will do the job. Be very careful to remove only the carbon deposits

- don't remove any metal and do not nick or scratch the sides of the ring grooves (see illustrations).

5 Once the deposits have been removed, clean the piston/rod assemblies with solvent and dry them with compressed air (if available). Make sure the oil return holes in the back sides of the ring grooves and the oil hole in the lower end of each rod are clear.

6 If the pistons and cylinder walls aren't damaged or worn excessively, and if the engine block is not rebored, new pistons won't be necessary. Normal piston wear appears as even vertical wear on the piston thrust surfaces and slight looseness of the top ring in its groove. New piston rings, however, should always be used when an engine is rebuilt.

7 Carefully inspect each piston for cracks around the skirt, at the pin bosses and at the ring lands.

8 Look for scoring and scuffing on the thrust faces of the skirt, holes in the piston crown and burned areas at the edge of the crown. If the skirt is scored or scuffed, the engine may have been suffering from overheating and/or abnormal combustion, which caused excessively high operating temperatures. The cooling and lubrication systems should be checked thoroughly. A hole in the piston crown is an indication that abnormal combustion

(pre-ignition) was occurring. Burned areas at the edge of the piston crown are usually evidence of spark knock (detonation). If any of the above problems exist, the causes must be corrected or the damage will occur again. The causes may include intake air leaks, incorrect air/fuel mixture, incorrect ignition timing and

EGR system malfunctions.

9 Corrosion of the piston, in the form of small pits, indicates that coolant is leaking into the combustion chamber and/or the crankcase.

Again, the cause must be corrected or the problem may persist in the rebuilt engine.

10 If in any doubt as to the condition of the pistons and connecting rods, have them inspected and measured by an engine

15.4a The ring grooves can be cleaned with a special tool, as shown here...

reconditioning specialist. If new parts are required, hw will be able to supply appropriate-sized pistons/rings, and rebore the cylinder block (where necessary).

16 Crankshaft -

inspection

inspection

1 Clean the crankshaft using paraffin or a suitable solvent, and dry it, preferably with compressed air if available. Be sure to clean the oil holes with a pipe cleaner or similar probe, to ensure that they are not obstructed.

Warning: Wear eye protection when using compressed air.

2 Check the main and big-end bearing journals for uneven wear, scoring, pitting and cracking.

3 Big-end bearing wear is accompanied by distinct metallic knocking when the engine is running (particularly noticeable when the engine is pulling from low speed) and some loss of oil pressure.

4 Main bearing wear is accompanied by severe engine vibration and rumble - getting progressively worse as engine speed increases

- and again by loss of oil pressure.

5 Check the bearing journal for roughness by running a finger lightly over the bearing surface. Any roughness (which will be accompanied by obvious bearing wear) indicates that the crankshaft requires regrinding (where possible) or renewal.

6 If the crankshaft has been reground, check for burrs around the crankshaft oil holes (the holes are usually chamfered, so burrs should not be a problem unless regrinding has been carried out carelessly). Remove any burrs with a fine file or scraper, and thoroughly clean the oil holes as described previously.

7 Have the crankshaft journals measured by an automotive engineering workshop. If the crankshaft is worn or damaged, they may be able to regrind the journals and supply suitable undersize bearing shells. If no undersize shells are available and the crankshaft has worn beyond the specified limits, it will have to be renewed. Consult your Toyota dealer or engine specialist for further information on parts availability.

|

|

|

|

|

Дата добавления: 2014-12-23; Просмотров: 534; Нарушение авторских прав?; Мы поможем в написании вашей работы!