КАТЕГОРИИ:

Архитектура-(3434)Астрономия-(809)Биология-(7483)Биотехнологии-(1457)Военное дело-(14632)Высокие технологии-(1363)География-(913)Геология-(1438)Государство-(451)Демография-(1065)Дом-(47672)Журналистика и СМИ-(912)Изобретательство-(14524)Иностранные языки-(4268)Информатика-(17799)Искусство-(1338)История-(13644)Компьютеры-(11121)Косметика-(55)Кулинария-(373)Культура-(8427)Лингвистика-(374)Литература-(1642)Маркетинг-(23702)Математика-(16968)Машиностроение-(1700)Медицина-(12668)Менеджмент-(24684)Механика-(15423)Науковедение-(506)Образование-(11852)Охрана труда-(3308)Педагогика-(5571)Полиграфия-(1312)Политика-(7869)Право-(5454)Приборостроение-(1369)Программирование-(2801)Производство-(97182)Промышленность-(8706)Психология-(18388)Религия-(3217)Связь-(10668)Сельское хозяйство-(299)Социология-(6455)Спорт-(42831)Строительство-(4793)Торговля-(5050)Транспорт-(2929)Туризм-(1568)Физика-(3942)Философия-(17015)Финансы-(26596)Химия-(22929)Экология-(12095)Экономика-(9961)Электроника-(8441)Электротехника-(4623)Энергетика-(12629)Юриспруденция-(1492)Ядерная техника-(1748)

Transmission. • The ball bearings and collar are press-fit on the transmission shafts

|

|

|

|

|

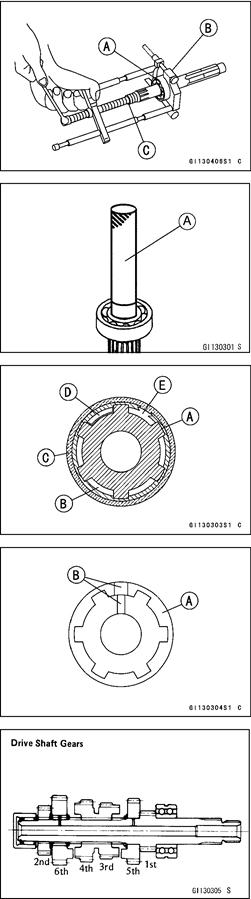

• The ball bearings and collar are press-fit on the transmission shafts. To remove the bearings [A], use a press or the bearing puller [B] and bearing puller adapter [C].

Special Tools - Bearing Puller: 57001-135

Bearing Puller Adapter: 57001-317

○The output shaft ball bearing, O-ring and collar ought to

be removed together. ○No need for the bearing puller adapter at output shaft.

Drive Shaft Assembly

Apply engine oil liberally to the drive shaft, gears, bearings and bushing.

Install the drive shaft ball bearing using the bearing driver [A].

Special Tool - Bearing Driver, 3 2: 57001-382

•○RA lewpalaycseinasntyalcl icrcirlciplispsth[aAt]wseorethraetmthoeveodpwenithingneiws aolnigense. d

with a spline groove [B], and install toothed washers [C] so that the teeth [D] are not aligned with the circlip opening [E]. To install a circlip without damage, fit the circlip onto the shaft expanding it just enough to install it, and use a suitable gear to push the circlip into place.

• When assembling the drive shaft 6th gear bushing [A] onto the shaft, align its oil hole [B] with the hole in the shaft.

• The drive shaft gears can be identified by size: the smallest diameter gear is 1st gear, and the largest is 6th. Be sure that all parts are put back in the correct sequence, facing the proper direction, and all circlips and washers are properly in place.

• Proper sequence starting with 1st gear (part of drive shaft) is: 1st gear, 5th gear (face the flat side of the gear to the right), washer, circlip, 3rd/4th gear (face 3rd gear side to the right), circlip, toothed washer, bushing (align the oil hole with the hole in the shaft), 6th gear (face the dogs to the right), toothed washer, circlip, 2nd gear, spacer, needle bearing, needle bearing outer race, and plug.

○The toothed washer before the bushing has slightly smaller teeth than the last one.

CRANKSHAFT/TRANSMISSION 9-29

|

|

|

|

|

Дата добавления: 2014-12-23; Просмотров: 380; Нарушение авторских прав?; Мы поможем в написании вашей работы!